Thermal Processes:

Surface Heat treatment, particularly those that undergo phase transformations like the martensitic reaction hardening of carbon steels, low alloy steels and cast irons - Laser, Flame, induction

Mechanical Processes

Cold working - surface by peening, shot blasting, explosive hardening or other specialised machining processes induce compressive stresses, increasing hardness and fatigue resistance. • Changing surface texture using machining and blasting.

Other Processes

Modification of surfaces by chemical/electro-etching, laser engraving, various chemical, solvent and ultrasonic cleaning processes could also be included here. Surface "Mo"

Surface Modification by Changing Surface Chemistry

Thermochemical Diffusion Processes –

Carburising (carburizing) – carbonitriding – nitridingnitrocarburising – boronising

Electrochemical Processes

Anodising (anodizing) of aluminium, titanium • Chemical Conversion Coatings – Phosphating chemical blacking chromating • Ion Implantation Processes

Ion Implantation Processes

Why Surface Modification By Chemical Means

To achieve desired surface properties which cannot be achieved by conventional alloying process & neither by mechanical means

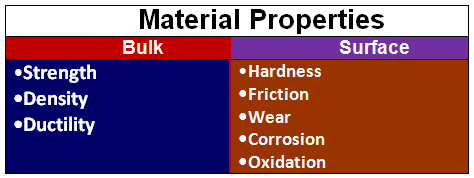

What are the surfaces Properties?

- Corrosion

- Oxidation

- Wear Erosion

- Abrasion Hardness